Jobsite Progress

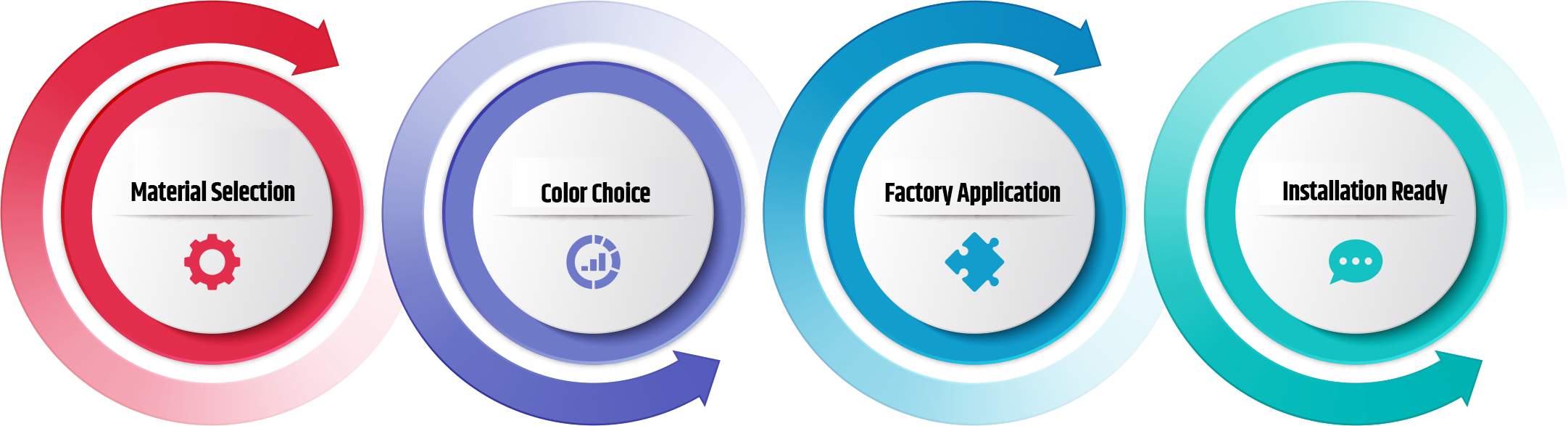

The true appeal of factory finishing is in the ease it creates for the project to keep progressing forward. Scaffolding can come down sooner, inclement weather is no longer your adversary, and nothing pops the appearance of your project more significantly than installed and finished materials.

Speed

The average prestain order takes 1 week to complete from the time the material is shipped to our factory to the time it is picked up and is ready for install. Multiple vendors, multiple profiles, multiple colors, if you can give us a week, we can get it finished.

Quality

We use the highest quality paints and stains from the biggest players in the market. With our machine line, you can rest assured we will never make an exception. Many of the products we are using have been strategically formulated for use in a controlled factory process. 20 Years’ worth of back testing our methods and procedures provides you supreme confidence in the quality of our craft.

Value

Painting is a costly, labor-intensive, endeavor. By Introducing automation to the trade we have been able to cut on-site painting costs by half. We pass this savings directly on to your project’s budget while also applying a back-seal on every exterior prestain order at no additional charge.